INSTA - COOL

- Point Of Use WFI Cooler -

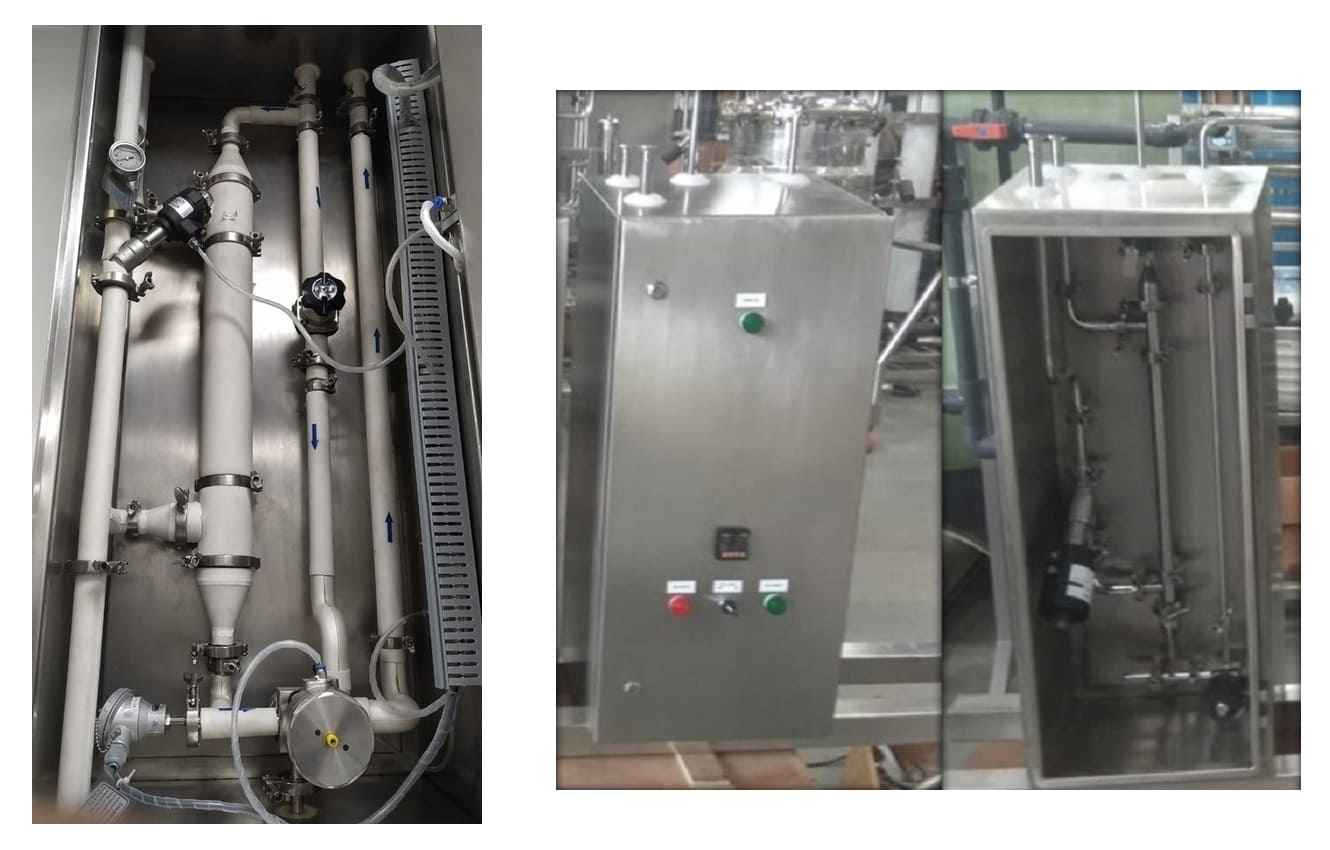

POU WFI Cooling Compact Solution

A Point of Use Water for Injection (WFI) Cooler is a system used in pharmaceutical and biotechnology industries to provide a continuous supply of high-purity water that meets the specifications required for the production of injectable drugs and other critical applications. WFI is water that has been purified to meet stringent quality standards, typically exceeding those of purified water (PW).

The Insta-Cool POU WFI Cooler is designed to dispense instant temperature controlled WFI. The POU’s meet the high quality requirements and hygienic standards of the pharmaceuticals Industry featuring compact, high performance sanitary shell and tube heat exchangers in the double tube sheet configuration. Many features and options can be customized.

Why Insta-Cool?

Insta Cool (i-COOL) is a compact solution for point of use cooling in Pharmaceutical Water Systems. Point of Use Cooler is designed considering important aspects of Pharma / Biotech / Vaccine industries. Designed flowrates in range of 100lph to 5000lph at any range of temperature. This smart module of point of user cooler is developed to control temperature of WFI instantly & effortlessly.

Major features of Insta-Cool are:

Unique Stand-Alone Unit with Compact Cabinet Design.

Sanitary Double Tube Sheet Shell & Tube Heat Exchanger.

Easy Installation and Ease to Operate the Hot & Cold Dispense.

Fully Automatic Operation with Emergency Stop Button.

Designed complies with ISPE Guideline and ASME BPE Compliant.

100% Drainability Product with Constant Flow & Temp dispense.

Insta-Cool POU Collors are CIP & SIP capable.

Sanitary design double tube sheet shaft & tube heat exchangers are compact in size, giving high heat transfer efficiency by using capillary tubes inside the shell, no scope for cross contamination & less pressure drop. Pipes & Fittings used in i-COOL are as per ASME BPE guidelines, export quality & of reputed makes. Works as subloop & complies ASME BPE guidelines, maintaining velocity of 1.2 m/s velocity to ensure no microbial growth in the systems. All Pipings are SS 316 L MOC, internally electro-polished and externally mirror polished as per ASME BPE Standard. All Gaskets USP Class VI Complaint Gaskets MOC Silicon / PTFE which can withstand High Temp. Chloride free PVDF insulation or High Temp Nitrile rubber are useds.

Several Advantages of i-Cool Installations

The "point of use" aspect refers to the fact that the WFI cooler is typically installed near the location where it will be used, rather than centrally producing and distributing WFI throughout the facility.

Reduced Piping and Distribution network. Minimized Dead Legs by using BLOCK valves. Efficient in Use of Energy & Quick Response to Demand. Simplified Compliance Validation & Flexibile Temperature Range. Designed with Double Tube Sheet HE to avoid cross contamination. Multiple POU to POU Communication with Advance Automation. NO MICROBIAL BREEDING by achieving appropriate velocity of (1.2m/sec). So i-Cool POU WFI Cooler is a Water Purification & Cooling System designed to meet the specific needs of Pharma & Biotechnology Industries for producing high-purity water and providing benefits in terms of efficiency, compliance & ease of maintenance.